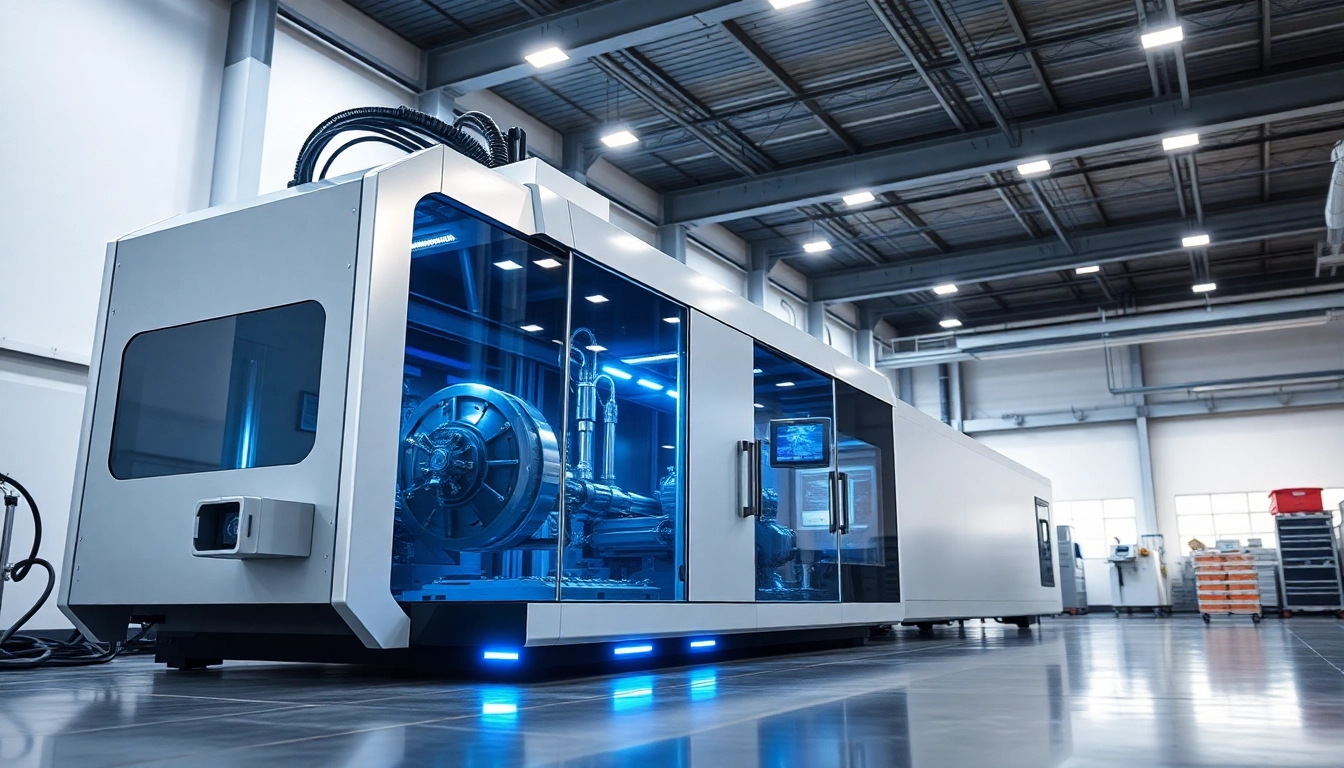

Understanding Injection Molding Machines

Injection molding machines are crucial in manufacturing plastic products, offering high efficiency and scalability. These machines can produce complex shapes and a vast array of products ranging from simple items to intricate designs. As industries evolve, the need for more precise and energy-efficient solutions has led to the development of advanced injection molding technologies. For those exploring options, Injection Molding Machine models from Topstar are among the most notable examples in this field.

What is an Injection Molding Machine?

An injection molding machine is a manufacturing tool used to produce parts by injecting molten material into a mold. Typical materials include thermoplastics, thermosetting polymers, and elastomers. The process involves melting the material, injecting it into a mold, cooling it, and then ejecting the solidified part. This method is highly efficient for producing large quantities of identical items, making it a go-to choice for industries such as automotive, consumer goods, and electronics.

How Injection Molding Works

The basic process of injection molding consists of several key steps:

- Material Feeding: Raw plastic pellets are stored in a hopper and fed into a heated barrel.

- Melting: The material is heated until it reaches a molten state through the application of heat and pressure.

- Injection: The molten plastic is injected into a closed mold cavity using a screw or ram mechanism.

- Cooling and Solidification: The molten material cools, solidifying in the shape of the mold.

- Ejection: Once cooled, the mold opens, and the finished part is ejected.

Types of Injection Molding Machines

Injection molding machines can be categorized into several types based on their mechanisms and the materials they can process:

- Hydraulic Injection Molding Machines: These machines use hydraulic systems for injection and clamping, offering good flexibility and power, but often at the cost of energy efficiency.

- Electric Injection Molding Machines: These models use electric motors for motion, providing precise control, energy efficiency, and lower operational costs.

- Hybrid Injection Molding Machines: Combining hydraulic and electric systems, hybrid machines aim to leverage the strengths of both technologies.

Key Features of Electric Injection Molding Machines

Electric injection molding machines are increasingly favored due to their numerous advantages. They provide significant enhancements in energy efficiency and output quality.

Energy Efficiency and Cost Savings

One of the primary benefits of electric injection molding machines is their energy efficiency. These machines consume less energy compared to hydraulic models, resulting in lower operating costs over time. For instance, electric machines can use up to 50% less energy during production, translating to significant savings, especially for high-volume manufacturers.

Precision and Accuracy in Production

Electric machines provide superior precision due to their advanced servo motor technology. This allows for fine-tuned control over injection speed and pressure, resulting in consistent part quality and reduced scrap rates. Manufacturers can achieve tighter tolerances and intricate designs that are often challenging with hydraulic counterparts.

Enhanced User Interfaces and Automation

Modern electric injection molding machines often come equipped with user-friendly interfaces that facilitate ease of use. Automation features such as real-time monitoring, predictive maintenance alerts, and remote access allow operators to streamline production processes and reduce downtimes. This not only enhances productivity but also improves overall operational efficiency.

The Advantages of Servo-Driven Injection Molding Machines

Servo-driven injection molding machines are a refined version of electric systems, offering additional benefits in control and automation.

Real-time Feedback and Control

Servo-driven systems provide real-time feedback on machine performance, enabling operators to adjust parameters instantly to optimize production. This capability enhances the adaptability of the manufacturing process and contributes to better product quality.

Integration with Robotics for Enhanced Efficiency

Integrating servo-driven machines with robotics allows for seamless operation from injection to part removal. This automation reduces manual labor, speeds up production cycles, and minimizes the risk of errors during handling. For example, a robotic arm can automatically pick and place finished components, increasing throughput and efficiency.

Improved Cycle Times and Product Quality

Thanks to precise control over every aspect of the injection molding cycle, servo-driven machines can reduce cycle times significantly. This results in increased productivity and lower costs per part, thereby offering a competitive edge in the marketplace.

Comparing Different Series of Injection Molding Machines

Topstar offers a range of injection molding machines, each tailored to meet specific needs and operational capacities.

TEII Series: All Electric Solutions

The TEII series from Topstar represents the pinnacle of all-electric injection molding technology. With clamping units featuring high-rigidity templates, these machines ensure product stability and mold protection. The modular design allows customization for various working conditions, making it ideal for manufacturers looking for versatility.

TMII Series: Servo-Driven Innovations

Topstar’s TMII series combines the precision of servo technology with innovative design, allowing control of multiple devices from a single interface. This integration leads to efficient production of complex, high-quality parts, including those with metal inserts. The synchronous operation enhances both speed and accuracy.

TH Series: Robust Direct Press Options

In contrast, the TH series provides robust solutions for direct pressing applications. These machines are designed with standardized platforms that accommodate large-format, deep-cavity molds. The two-plate clamping structure maximizes mold opening strokes, catering to industries requiring large-scale production.

Future Trends in Injection Molding Technology

The injection molding industry is continually evolving, becoming more efficient, sustainable, and integrated with advanced technologies.

The Move Towards Sustainability in Manufacturing

As industries face increasing pressure to adopt sustainable practices, injection molding technology is shifting towards eco-friendly materials and processes. Manufacturers are exploring bioplastics and recycled materials, minimizing waste in production while maintaining high-quality standards.

Emerging Technologies to Watch in 2025

The future will see the incorporation of artificial intelligence (AI) and machine learning (ML) in injection molding processes. These technologies will allow for predictive analytics, optimizing production schedules and minimizing downtime through enhanced real-time monitoring systems.

Adapting to Market Demands and Consumer Needs

To remain competitive, manufacturers must adapt quickly to changing market demands. This includes producing smaller batch sizes and customized products efficiently. Flexible manufacturing solutions, such as on-demand injection molding and rapid prototyping capabilities, will become essential for manufacturers navigating the challenges of changing consumer preferences.